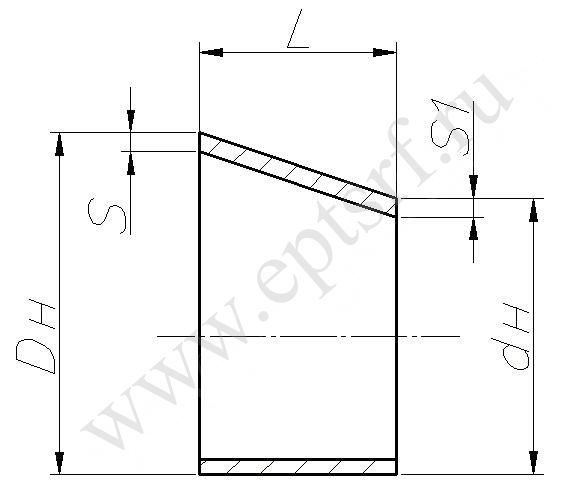

Переход эксцентрический ТУ 1469-003-42039714-2004

Переходы штампосварные эксцентрические ТУ 1469-003-42039714-2004 из малоуглеродистой и низколегированной сталей, предназначенные для трубопроводов различного назначения, включая магистральные, промысловые трубопроводы и объекты нефтяной и газовой промышленности, транспортирующие неагрессивные нефть, газ и др. продукты, а также из нержавеющих сталей, предназначенные для трубопроводов, транспортирующих неагрессивные, малоагрессивные и агрессивные продукты. Применяются при температуре от минус 70 до плюс 1500С при PN (Ру) до 12,5 МПа. Изготавливаются в двух исполнениях: УХЛ – для макроклиматических районов с умеренным и холодным климатом, У – для макроклиматических районов с умеренным климатом с коэффициентами условий работы штампосварных деталей m=0,6; 0,75. Переходы изготавливаются из сталей следующих классов прочности: К42, К46, К48, К50, К52, К54, К56, К60.

Минимальные номинальные значения толщин стенок, ст.09Г2С ГП-К48

| Dн-dн | 1,6МПа | 2,5МПа | 4МПа | ||||||||||

| L, | |||||||||||||

| мм | S | S1 | S | S1 | S | S1 | S | S1 | S | S1 | S | S1 | мм |

| 377х325 | 4,0 | 4,0 | 4,0 | 4,0 | 4,0 | 4,0 | 4,0 | 4,0 | 4,5 | 4,0 | 4,0 | 4,0 | 295 |

| 426х325 | 4,0 | 4,0 | 4,0 | 4,0 | 4,0 | 4,0 | 4,0 | 4,0 | 5,0 | 4,0 | 4,0 | 4,0 | 250 |

| 530х325 | 5,0 | 4,0 | 5,0 | 4,0 | 5,0 | 4,0 | 5,0 | 4,0 | 6,0 | 4,0 | 5,0 | 4,0 | 495 |

| 530х426 | 5,0 | 4,5 | 5,0 | 4,0 | 5,0 | 4,0 | 5,0 | 4,0 | 6,0 | 5,0 | 5,0 | 4,0 | 530 |

| 630х325 | 6,0 | 4,0 | 6,0 | 4,0 | 6,0 | 4,0 | 6,0 | 4,0 | 8,0 | 4,0 | 6,0 | 4,0 | 750 |

| 630х426 | 6,0 | 4,5 | 6,0 | 4,0 | 6,0 | 4,0 | 6,0 | 4,0 | 8,0 | 5,0 | 6,0 | 4,0 | 490 |

| 630х530 | 6,0 | 5,0 | 6,0 | 5,0 | 6,0 | 5,0 | 6,0 | 5,0 | 8,0 | 6,0 | 6,0 | 5,0 | 240 |

| 720х426 | 6,0 | 4,5 | 6,0 | 4,0 | 6,0 | 4,0 | 5,0 | 4,0 | 9,0 | 5,0 | 7,0 | 4,0 | 700 |

| 720х530 | 6,0 | 5,0 | 6,0 | 5,0 | 6,0 | 5,0 | 5,0 | 5,0 | 9,0 | 6,0 | 7,0 | 5,0 | 460 |

| 720х630 | 6,0 | 6,0 | 6,0 | 6,0 | 6,0 | 6,0 | 5,0 | 6,0 | 9,0 | 8,0 | 7,0 | 6,0 | 220 |

| 820х530 | 7,0 | 5,0 | 7,0 | 5,0 | 7,0 | 5,0 | 5,0 | 5,0 | 10,0 | 6,0 | 8,0 | 5,0 | 690 |

| 820х630 | 7,0 | 6,0 | 6,0 | 6,0 | 7,0 | 6,0 | 5,0 | 6,0 | 10,0 | 8,0 | 8,0 | 6,0 | 460 |

| 820х720 | 7,0 | 6,0 | 6,0 | 6,0 | 7,0 | 6,0 | 5,0 | 5,0 | 10,0 | 9,0 | 8,0 | 7,0 | 240 |

| 1020х630 | 8,0 | 6,0 | 6,0 | 6,0 | 8,0 | 6,0 | 6,0 | 6,0 | 12,0 | 8,0 | 10,0 | 6,0 | 940 |

| 1020х720 | 8,0 | 6,0 | 6,0 | 6,0 | 8,0 | 6,0 | 6,0 | 5,0 | 12,0 | 9,0 | 10,0 | 7,0 | 720 |

| 1020х820 | 8,0 | 7,0 | 7,0 | 6,0 | 8,0 | 7,0 | 6,0 | 5,0 | 12,0 | 10,0 | 10,0 | 8,0 | 480 |

| 1220х820 | 10,0 | 10,0 | 10,0 | 10,0 | 10,0 | 10,0 | 10,0 | 10,0 | 14,0 | 10,0 | 11,0 | 10,0 | 960 |

| 1220х1020 | 10,0 | 10,0 | 10,0 | 10,0 | 10,0 | 10,0 | 10,0 | 10,0 | 14,0 | 12,0 | 11,0 | 10,0 | 490 |

| 1420х1020 | 12,0 | 10,0 | 12,0 | 10,0 | 12,0 | 10,0 | 12,0 | 10,0 | 16,0 | 12,0 | 13,0 | 10,0 | 960 |

| 1420х1220 | 12,0 | 10,0 | 12,0 | 10,0 | 12,0 | 10,0 | 12,0 | 10,0 | 16,0 | 14,0 | 13,0 | 11,0 | 490 |

| Dн-dн | 5,6МПа | 6,4МПа | 7,5МПа | ||||||||||

| L, | |||||||||||||

| мм | S | S1 | S | S1 | S | S1 | S | S1 | S | S1 | S | S1 | мм |

| 377х325 | 6,0 | 6,0 | 5,0 | 4,5 | 7,0 | 6,0 | 6,0 | 5,0 | 8,0 | 7,0 | 7,0 | 6,0 | 295 |

| 426х325 | 7,0 | 6,0 | 6,0 | 4,5 | 8,0 | 6,0 | 7,0 | 5,0 | 9,0 | 7,0 | 8,0 | 6,0 | 250 |

| 530х325 | 9,0 | 6,0 | 7,0 | 4,5 | 10,0 | 6,0 | 8,0 | 5,0 | 11,0 | 7,0 | 9,0 | 6,0 | 495 |

| 530х426 | 9,0 | 7,0 | 7,0 | 6,0 | 10,0 | 8,0 | 8,0 | 7,0 | 11,0 | 9,0 | 9,0 | 8,0 | 530 |

| 630х325 | 10,0 | 6,0 | 8,0 | 4,5 | 12,0 | 6,0 | 9,0 | 5,0 | 13,0 | 7,0 | 11,0 | 6,0 | 750 |

| 630х426 | 10,0 | 7,0 | 8,0 | 6,0 | 12,0 | 8,0 | 9,0 | 7,0 | 13,0 | 9,0 | 11,0 | 8,0 | 490 |

| 630х530 | 10,0 | 9,0 | 8,0 | 7,0 | 12,0 | 10,0 | 9,0 | 8,0 | 13,0 | 11,0 | 11,0 | 9,0 | 240 |

| 720х426 | 12,0 | 7,0 | 9,0 | 6,0 | 13,0 | 8,0 | 11,0 | 7,0 | 15,0 | 9,0 | 12,0 | 8,0 | 700 |

| 720х530 | 12,0 | 9,0 | 9,0 | 7,0 | 13,0 | 10,0 | 11,0 | 8,0 | 15,0 | 11,0 | 12,0 | 9,0 | 460 |

| 720х630 | 12,0 | 10,0 | 9,0 | 8,0 | 13,0 | 12,0 | 11,0 | 9,0 | 15,0 | 13,0 | 12,0 | 11,0 | 220 |

| 820х530 | 13,0 | 9,0 | 11,0 | 7,0 | 15,0 | 10,0 | 12,0 | 8,0 | 17,0 | 11,0 | 14,0 | 9,0 | 690 |

| 820х630 | 13,0 | 10,0 | 11,0 | 8,0 | 15,0 | 12,0 | 12,0 | 9,0 | 17,0 | 13,0 | 14,0 | 11,0 | 460 |

| 820х720 | 13,0 | 12,0 | 11,0 | 9,0 | 15,0 | 13,0 | 12,0 | 11,0 | 17,0 | 15,0 | 14,0 | 12,0 | 240 |

| 1020х630 | 16,0 | 10,0 | 13,0 | 8,0 | 18,0 | 12,0 | 15,0 | 9,0 | 21,0 | 13,0 | 17,0 | 11,0 | 940 |

| 1020х720 | 16,0 | 12,0 | 13,0 | 9,0 | 18,0 | 13,0 | 15,0 | 11,0 | 21,0 | 15,0 | 17,0 | 12,0 | 720 |

| 1020х820 | 16,0 | 13,0 | 13,0 | 11,0 | 18,0 | 15,0 | 15,0 | 12,0 | 21,0 | 17,0 | 17,0 | 14,0 | 480 |

| 1220х820 | 19,0 | 13,0 | 16,0 | 11,0 | 22,0 | 15,0 | 18,0 | 12,0 | 26,0 | 17,0 | 17,0 | 14,0 | 960 |

| 1220х1020 | 19,0 | 16,0 | 16,0 | 13,0 | 22,0 | 18,0 | 18,0 | 15,0 | 26,0 | 21,0 | 17,0 | 17,0 | 490 |

| 1420х1020 | 23,0 | 16,0 | 18,0 | 13,0 | 26,0 | 18,0 | 21,0 | 15,0 | 30,0 | 21,0 | 17,0 | 17,0 | 960 |

| 1420х1220 | 23,0 | 19,0 | 18,0 | 16,0 | 26,0 | 22,0 | 21,0 | 18,0 | 30,0 | 26,0 | 21,0 | 17,0 | 490 |

| Dн-dн | 8,5МПа | 10МПа | 12,5МПа | ||||||||||

| L, | |||||||||||||

| мм | S | S1 | S | S1 | S | S1 | S | S1 | S | S1 | S | S1 | мм |

| 377х325 | 9,0 | 8,0 | 8,0 | 7,0 | 11,0 | 9,0 | 9,0 | 8,0 | 13,0 | 11,0 | 11,0 | 9,0 | 295 |

| 426х325 | 10,0 | 8,0 | 8,0 | 7,0 | 12,0 | 9,0 | 10,0 | 8,0 | 15,0 | 11,0 | 12,0 | 9,0 | 250 |

| 530х325 | 13,0 | 8,0 | 10,0 | 7,0 | 15,0 | 9,0 | 12,0 | 8,0 | 18,0 | 11,0 | 15,0 | 9,0 | 495 |

| 530х426 | 13,0 | 10,0 | 10,0 | 8,0 | 15,0 | 12,0 | 12,0 | 10,0 | 18,0 | 15,0 | 15,0 | 12,0 | 530 |

| 630х325 | 15,0 | 8,0 | 12,0 | 7,0 | 18,0 | 9,0 | 14,0 | 8,0 | 22,0 | 11,0 | 18,0 | 9,0 | 750 |

| 630х426 | 15,0 | 9,0 | 12,0 | 8,0 | 18,0 | 12,0 | 14,0 | 10,0 | 22,0 | 15,0 | 18,0 | 12,0 | 490 |

| 630х530 | 15,0 | 13,0 | 12,0 | 10,0 | 18,0 | 15,0 | 14,0 | 12,0 | 22,0 | 18,0 | 18,0 | 15,0 | 240 |

| 720х426 | 17,0 | 9,0 | 14,0 | 8,0 | 20,0 | 12,0 | 16,0 | 10,0 | 25,0 | 15,0 | 20,0 | 12,0 | 700 |

| 720х530 | 17,0 | 13,0 | 14,0 | 10,0 | 20,0 | 15,0 | 16,0 | 12,0 | 25,0 | 18,0 | 20,0 | 15,0 | 460 |

| 720х630 | 17,0 | 15,0 | 14,0 | 12,0 | 20,0 | 18,0 | 16,0 | 14,0 | 25,0 | 22,0 | 20,0 | 18,0 | 220 |

| 820х530 | 19,0 | 13,0 | 16,0 | 10,0 | 23,0 | 15,0 | 18,0 | 12,0 | 28,0 | 18,0 | 23,0 | 15,0 | 690 |

| 820х630 | 19,0 | 15,0 | 16,0 | 12,0 | 23,0 | 18,0 | 18,0 | 14,0 | 28,0 | 22,0 | 23,0 | 28,0 | 460 |

| 820х720 | 19,0 | 17,0 | 16,0 | 14,0 | 23,0 | 20,0 | 18,0 | 16,0 | 28,0 | 25,0 | 23,0 | 20,0 | 240 |

| 1020х630 | 24,0 | 15,0 | 20,0 | 12,0 | 28,0 | 18,0 | 23,0 | 14,0 | 35,0 | 22,0 | 28,0 | 18,0 | 940 |

| 1020х720 | 24,0 | 17,0 | 20,0 | 14,0 | 28,0 | 20,0 | 23,0 | 16,0 | 35,0 | 25,0 | 28,0 | 20,0 | 720 |

| 1020х820 | 24,0 | 19,0 | 20,0 | 16,0 | 28,0 | 23,0 | 23,0 | 18,0 | 35,0 | 28,0 | 28,0 | 23,0 | 480 |

| 1220х820 | 24,0 | 19,0 | 20,0 | 16,0 | 28,0 | 23,0 | 23,0 | 18,0 | 35,0 | 28,0 | 28,0 | 23,0 | 960 |

| 1220х1020 | 24,0 | 24,0 | 20,0 | 20,0 | 28,0 | 28,0 | 23,0 | 23,0 | 35,0 | 35,0 | 28,0 | 28,0 | 490 |

| 1420х1020 | 33,0 | 24,0 | 27,0 | 20,0 | 39,0 | 28,0 | 32,0 | 23,0 | 48,0 | 35,0 | 39,0 | 28,0 | 960 |

| 1420х1220 | 33,0 | 24,0 | 27,0 | 20,0 | 39,0 | 28,0 | 32,0 | 23,0 | 48,0 | 35,0 | 39,0 | 28,0 | 490 |

Пример условного обозначения:

Переход штампосварной эксцентрический из материала класса прочности К48, с размерами присоединяемых труб 720х16мм и 530х12мм, на рабочее давление 7,5 МПа при коэффициенте условий работы m=0,6 для макроклиматических районов с холодным климатом:

Переход ЭПШС 720х16 К48-530х12-7,5-0,6-УХЛ ТУ 1469-003-42039714-2004